Images are for representation only.

© Copyright 2020 INDANA STEEL PVT LTD. All Rights Reserved.

Similar to the Valves of the heart, In a piping system also Valves regulates, controls, isolates and directs the flow of the fluid. Valves alone account for almost 10 percent of the cost of total piping system. In ancient times tree branches were used to regulate water. The Roman Empire was unmatchable in early days in controlling and storage of fresh waters. In fact, the castellum was the first water Sewerage system in the historic city of Pompeii. The distribution and regulation of water from the aqueduct through 3 outlets was done by the castellum. Egg shaped Lead Pipe was used in the transportation of water. Unfortunately, the ancient city of Pompeii was buried under the volcanic eruption of Mount Vesuvius in 79 AD. The excavations have led to the finding of bronze valves which were used to pump water uphill to the castellum.

In a Modern piping system Valves alone account for almost 10 percent of the cost of total piping system. Few types of Commonly used Industrial Valves:

Most of the Valves leak and spray outs with time and is very common to the industrial setting. Primary reasons being:

1. Cannot be closed due to foreign particles, dust and debris.

2. Seat or the seal of the Valve gets damaged with time.

3. Maintenance failure.

These leakages have been d fined by various standards like API,ANSI,MSS,FCI etc.

Many of the catastrophic accidents in the past have been due to Valve leakages and subsequent splash.

Industrial Valves Are regulating devices which at any given time are holding high pressure fluids. Primarily

because of two reasons valve leaks are more dangerous compared to Flange leaks:

1. Imagine a close valve leaking which is holding a high-pressure fluid whereas In most cases flange are subject

to fluid movement.

2. Valves have been designed to operate so the worker interference is not limited whereas flanges have limited interference mostly during maintenance.

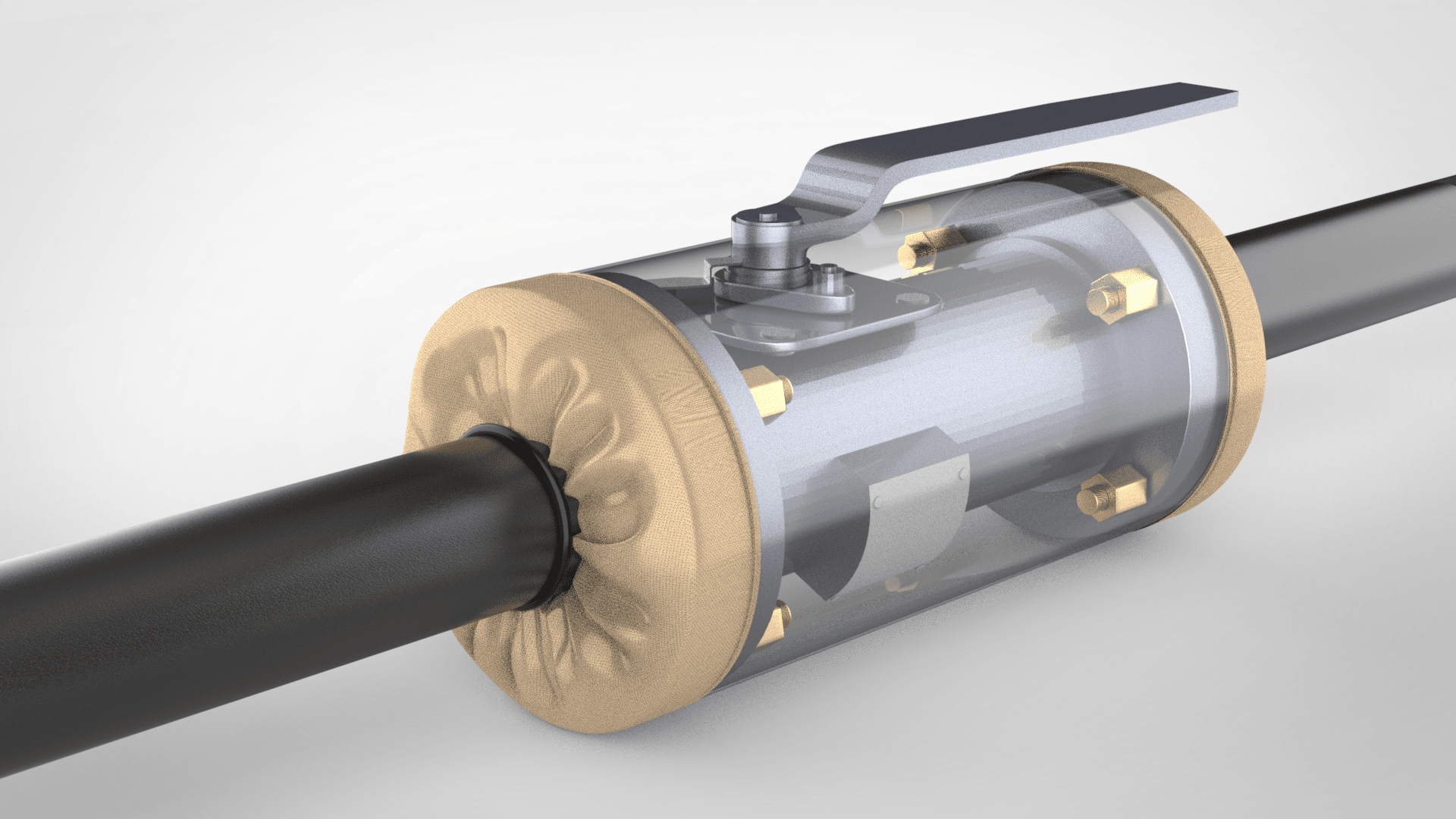

These reasons makes a Valve Spray out very dangerous. We have specially designed Valve Spray shields to contain these leaks and keep your manpower safe at all times. Installation of Valve Spray Shields and valve guards also increases you workers morale while handling these equipment. Valves shields come in three types of material commonly:

1. Teflon coated fibreglass Spray shields with dual locking

2. Teflon Coated Fibreglass Spray shields with visual inspection window and dual locking (Clear Type)

3. Stainless steel Grade 316 shields for high temperature and highly corrosive environment.

Every Valve spray shield is tested for appropriate pressure requirement at our pressure testing rig. These Valve shields are specially stitched with Kevlar threads giving it very high strength. Cotton or nylon stitched valve guards may come out during a leak as these threads are not designed to handle such kind of environment and pressure. Material used in these Valve shields are flame resistant and Teflon / Kevlar braided ropes give the valve shields its much-desired pressure holding strength. Every Indana Valve spray shield is a life saving and equipment saving device.

Images are for representation only.

© Copyright 2020 INDANA STEEL PVT LTD. All Rights Reserved.